Enertechnic sa

Heating - Cooling DHW & Industrial Process Systems

.png)

WORLD'S BEST TECHNOLOGY IN SOLAR ENERGY

Solar Collectors "MAG" For Central Systems with Vacuum

Tubes of Copper and Glass in Paraboloid Reflectors

.png)

4 Times M

ore Effective Using 1/4 of

the Space Required

.png)

.jpg)

.jpg)

Detailed description of MAG vacuum tube solar collector Consisting of three walls vacuum tube, in the focus of a high performance parabolic reflector with high efficiency at high operational temperatures that can also be a hot water storage device (for 40-60% of the total heating water volume) at open circuit systems. A glass tube 150mm in diameter and a thickness of 3mm, which surrounds the copper pipe (120mm and thickness 1mm), closed at both ends in order to form the heating water mass into a thin ring directly below the selective surface.

The bottoms of the glass tube are sealed with a special material that keeps its elasticity during the year and keeps the high vacuum (10-4 bar in operational temperatures) and withstands operating temperatures up to 150oC.

The bottoms of the sealed vacuum tube are covered with aluminium shells which are filled with polyurethane insulation and are firmly supported on the focus of a parabolic reflector 0,87m2/MAG width (useful surface) with reflectance factor 93%

Technical Characteristics

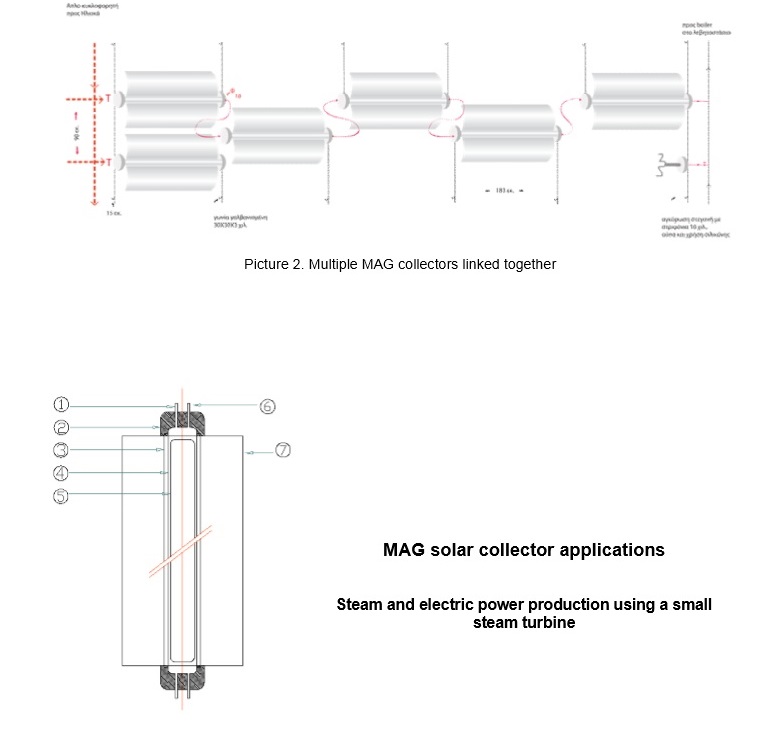

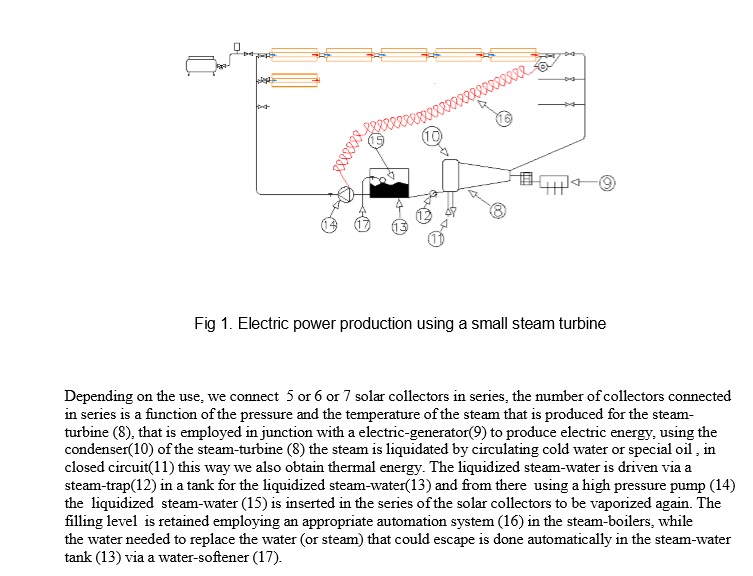

Technical Characteristics Three wall solar vacuum collector (closed circuit) located in the focus of a fixed semi-cylindrical reflector(7) .The silicon used for sealing (2) the edges of the glass-tube (3), that contains the iron-tube (4) as a third wall, and the vacuum can withstand high temperatures of 3000C or even 4000C, while the tubes (4,5) are made of iron-tubes or seamless tubes or stainless steel pipes, and both the inner tube (5) and the outer tube (4) are sealed and can bear pressure of 20 bar or even 60 bar. Furthermore, they have a big diameter so that the focal points of the sun rays are concentrated throughout the whole day on the selective surface off the outer tube (4) without moving the reflector (7). The ring of the outer tube (4) is half filled with water in order to facilitate the vaporization and the vacuum tubes are interconnected via pairs of small tubes over and under each bottom allowing the water circulate in the bottom (1) and allowing the steam at the top (6) to pass from tube to tube of each series of collectors.

Desalination System

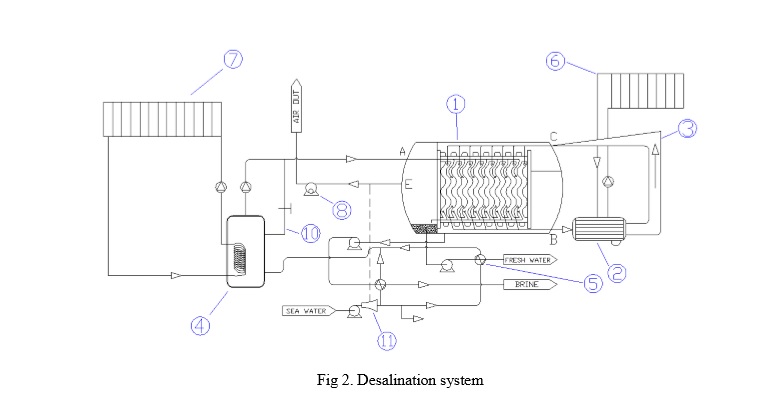

Distillation and desalination vacuum system of salt or semi-salt water using solar energy, heating the salt water in an insulated boiler (4) (Fig.2). With a recirculation hot water (10) closed circuit via MAG vacuum tube solar collectors with high efficiency ratio under high working pressures (7).

Hot salt water enters a special flat plate heat exchanger (1), in the entrance (Α) through a circulator, in order to cool and liquefy the produced steam that entered in (C) the heat exchanger (1) with higher temperature and under greater pressure. Most of the incoming salt water vaporizes taking advantage of the latent heat from the condensing steam, while downwards in a big tank the high density salt water is collected and removed after it pre-heats incoming seawater through a cross flow type heat exchanger, always with the help of a circulator. Gasification takes place in a low temperature vacuum environment (Ε), either with the help of an ejector pump (11) (Fig.2) or with a vacuum pump (8) (Fig.2). Liquefied fresh water leaves the system through a one-way valve at high temperature and through a simple cross flow type heat exchanger (5) is cooled, pre-heating at the same time incoming sea water. The out coming steam, pressure and temperature rise (crucial point of the invention) is achieved either with a special heat exchanger (2) and a hot water closed circuit using solar collectors (6) or with a special steam compression pump

ΕΝERTECHNIC technology, for your information...

(www.enertechnic.eu)

MAG SPACE VACUUM TECHNOLOGY is a technology developed in Greece for solar energy collection. The technology uses a three-wall vacuum tube (large diameter), the focal point being a fixed direction semi-cylindrical paraboloid reflector, which directs sunlight to focal points along the tube’s outer surface during the day, facilitating absorption in the selective black titanium coated metal inner tube, which is contained within a high-vacuum glass outer tube. The maximum absorption of thermal radiation (infrared) is r = 95%-97% and the lowest re-emission coefficient e = 2-3% (radiation loss).

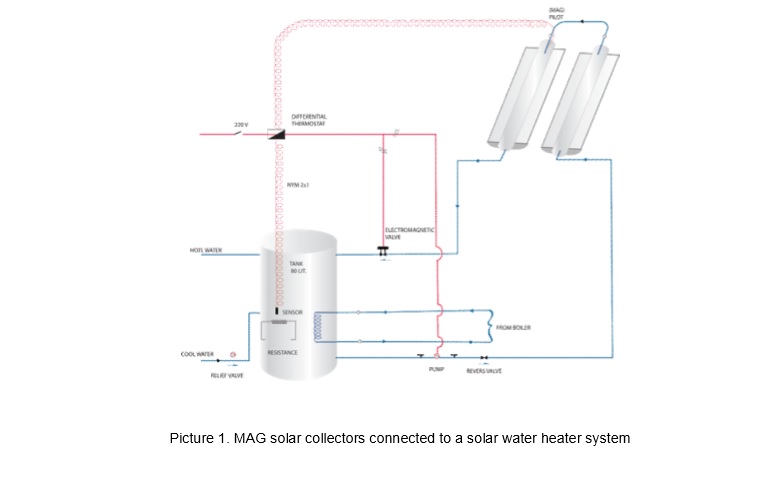

Our technology means we can guarantee high level efficiency at high operating temperatures, whether for hot water for residential use (with automatic thermostatic mixing solar boilers), or in hotels or hospitals, or for home heating (either underfloor heating or radiators, open loop collectors with or without hot water storage tanks VMAG= 22lit/MAG), or for industrial use, including air conditioning and desalination (using closed loop MAG collectors, V MAG = 5,5 lit.).

Water Heater -->

.png)

With mix valve.[200 lit./day use hot water 400C. OPEN SYSTEM ( VMAG =22 lit. + VBOILER = 60 lit.) = 82 lit.800C. + 82 lit. 200C. = 164 lit. 500C. or 230 lit. 400C.! ]

Our company has been successfully installing these types of systems for more than 12 years now, with excellent results, (for example, 95% savings at a 700-bed hotel in Crete under the ENERGY PLAN (2000-2004) for its 6-month summer season, certified by CRES telemetering). The dependability of our original SPACE TECHNOLOGY vacuum systems has been proven for over 20 years now!!

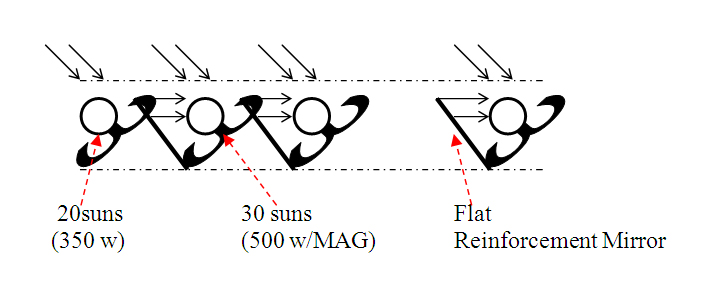

Given use of the correct type of paraboloid stable reflectors installed sufficiently far apart so that the reflectors do not overshadow each other, it becomes possible to install a flat booster mirror in the gap, at the appropriate angle, which can increase incident radiation by 50% during solar noon hours (10:30 to 15:00) in rear MAG+ solar collectors mounted in parallel. This increases output from these collectors by 40%! In other words, if the average summer output in Greece is 5,000 Kcal/MAG*day,[ opening of parabolic mirror 0,60 m. x 1,77m.] the booster mirror will mean production equivalent to:

1.4 x 5.000 Kcal/ MAG+*day = 7.000 Kcal/ MAG+*day

[ older opening of parabolic mirror was 0,50m. x 1,77 m. and then we have 4.300 Kcal./MAG. Day. Average summer output in Greece ].

OLD OPENIG (0,50.x1,77m.) EXABLE :

5.000 Kcal/ MAG + 40% = 7.000 Kcal/ MAG+

Of course, to ensure that service maintenance inspections can take place in all locations, booster mirrors must be mounted in a central cluster together with the MAG collectors, with 85% coverage; the average daily summer output increase of a cluster like this will be equivalent to Q = 0.85 x 0.40 x 5.000 Kcal/ MAG+*day = 1.700 Kcal/ MAG+*day and the cluster will give:

5.000+ 1.700 = 6,700 Kcal/ MAG+*day (= 7,8 Kwh/MAG+. day.)

Other collectors available on the market would require installations covering a much larger area in order to reach the same level of output, which would also multiply the cost! MAG TECHNOLOGY has also been developed for superheated steam MAG collectors of 280oC and 12.5 BAR, which can produce electricity using steam turbines. Steam condensers can also produce much higher quantities of thermal energy, with depreciation of investment achievable within 3 years!!

Furthermore, MAG cylindrical photovoltaic collectors, using water-cooled concentrator cells installed at the focal points of a fixed position paraboloid reflector, have now been developed so that electricity can be produced in tandem with thermal energy. These types of collector only occupy about 40% of the surface area compared to other systems!!

REPORT OF MUNICH FAIR (4 – 6 - June 2014) .

1) MAG Technology is a special distinct technology among competition. Its interesting part is “ Space Vacuum Technology “ ( to retaining high vacuum of 10 – 4BAR and in high temperatures up to 3000 C. (Vacuum heat produced), held between glass tube and iron pipes, which have different coefficients of expansion when heated). Our vacuum technology is very reliable once it is tested, applied and held successfully in units produced in 1992!

2) Our vacuum tube of a large diameter placed in focus of a stable semi cylindrical paravoloid mirror in order to collect surface all linear rays of the daily sunshine, using Black Titanium, achieved without movements of the parabolic mirror. The metal pipe is disposed co-axially inside the second tube, closed at both ends, so as to limit the content to heating water or liquid a ring of 5,5 liters. And for a closed circuit operation, to be heated quickly to the collector. Moreover, we have the option to use in high quality hot water use installations, open circuit collectors with galvanized metal pipe and heated water volume 22 l. / MAG (collector). The daily efficiency degree of the collector MAG is n = 0,78! in the temperature range of 35 0 C. to 65 0 C.

3) With a collector MAG, closed circuit, and open mirror (0.60 m X 1.77 m) and a boiler 120 lit. double wall (jacket), hot water housing, we average summer performance 280 l. / Day water use 40 0 C. For about the same effect flat technology collectors must place 4 m2 and a boiler of 200 lit. When we are compared with other vacuum tubes without properly parabolic or no parabolic mirror at all, we estimate that they would need to place from 25 to 30 vacuum tubes in custom above boiler 150 lit. SO THE PRICE IS similar industry-wide, but we are using ½ of space and we achieve almost zero visual pollution.

4) These 200 liters hot water production cannot be compared with MAG Technology, once when we place a 200 lit boiler, in a closed circuit, and we add two parallel connected modules MAG, we produce 380 liters per day of 40c in a very competitive price.

Moreover, when we add the flat enhancement mirror then the whole system delivers 470 lit/day using an automatic thermostatic mixing valve. The latest technological improvement adds a +40% thermal result with a cost of 110 EUR per system.

5) Due to the stable parabolic mirror the additional flat enhancement mirror delivers this 40% additional result in calories when the cost is not more than 10% of the whole systems cost in the case of central installations! This latest improvement makes our system unmatched compared to any other form of solar panels, for central facilities. For residential heating, air conditioning, hot water for hotels, hospitals, industrial various uses or Desalination. On the contrary the technology of moving parabolic cannot be enhanced and loses this low cost advantage.

MAG TECHNOLOGY IS INTERNATIONALLY RECOGNISED AND WE ARE PROUD OF ITS CONTINUED SUCCESS DESPITE THE CURRENT DIFFICULT ECONOMIC CLIMATE FACING OUR COUNTRY!!